Agitation

The term ’agitation’ subsumes different ways of homogenising the substrate or mixing it with

water and co-substrate:

• Mixing and homogenizing the substrate in the mixing chamber

• Agitation inside the digester

• Poking through the in- and outlet pipes (small scale plants)

Agitation of the digester contents is important for the trouble-free performance of a biogas-

plant. For the following reasons agitation is recommended several times a day:

• to avoid and destroy swimming and sinking layers

• to improve the activity of bacteria through release of biogas and provision of fresh

nutrients

• to mix fresh and fermenting substrate in order to inoculate the former

• to arrive at an even distribution of temperature thus providing uniform conditions

inside the digester

Even without mixing device, there is a certain agitation through the raising gas, through the

movement of substrates with different temperatures and by the inflow of fresh substrate. This

agitation, however, is usually insufficient. A well agitated substrate can, leaving other

parameters constant, increase it’s biogas production by 50%.

Agitation, as a general rule, should be performed as much as necessary but as little as

possible. Too frequent mixing with fast rotating, mechanical agitation devices can disturb the

biological processes in the fermenting substrate. In addition, an all-too thorough mixing of the

whole digester contents may lead to half-digested substrate leaving the digester prematurely.

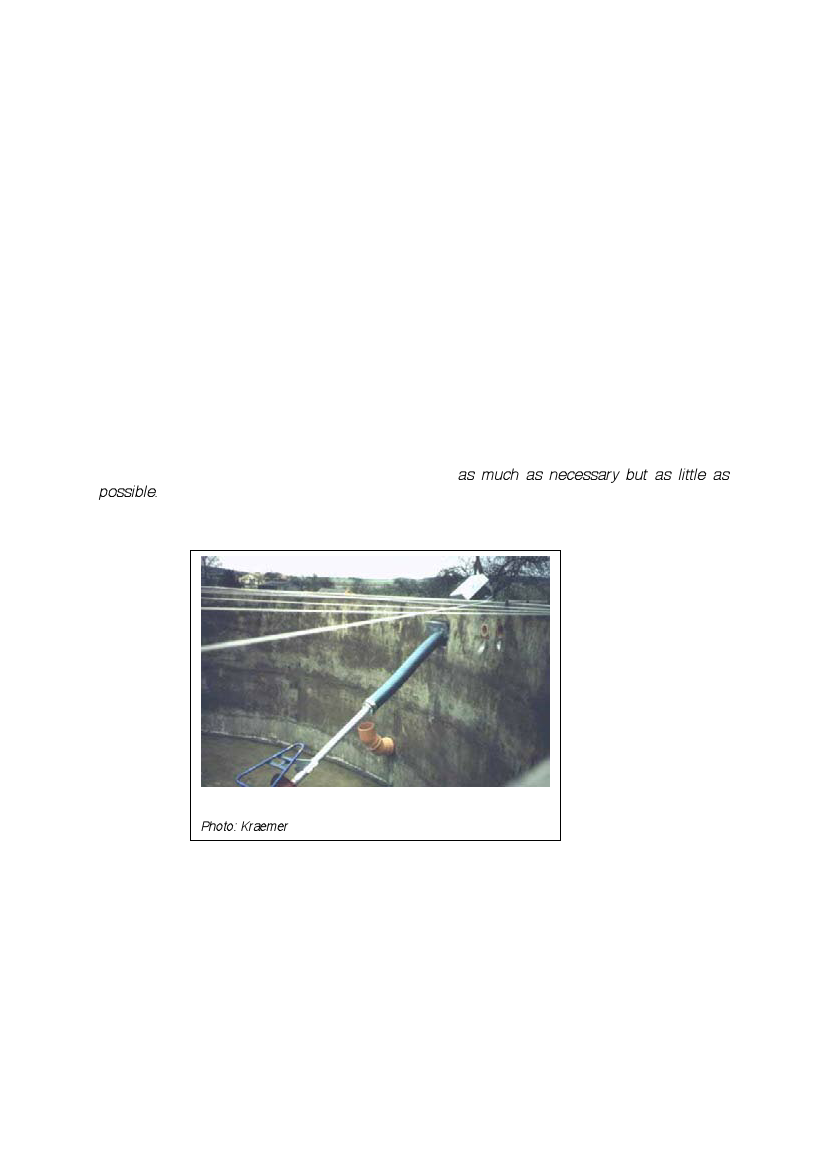

Figure 32: Mixing device in an agricultural digester under

construction

Photo: Kraemer

Mixing methods

Simple mixing methods have been installed mainly in developing countries:

• tangential inlet and outlet pipes

• separation walls

• forced substrate flow

• vertical hand-operated rotors

• horizontal, hand-operated paddle rotors

• poking through inlet and outlet

55